Here are some quick and witty tips to help you pick the perfect spring materials for your needs:

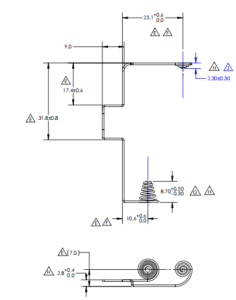

1. Compression Spring

– Common Materials:

– Carbon Steel (60#, 65#): Perfect for everyday use, wallet-friendly, but not so great in the corrosion department.

– Stainless Steel (302, 304, 316): Great for tough environments (think medical equipment or outdoor gear), a little pricier, but strong on the rust resistance.

– Alloy Steel (50CrV): Built for the heavy hitters—high loads and high temps, this one’s for the big jobs.

– Tip:

– Indoor? Carbon steel’s got your back.

– Outdoors or in humid, salty spots? Go for stainless steel.

– High loads or heat? Alloy steel is your friend.

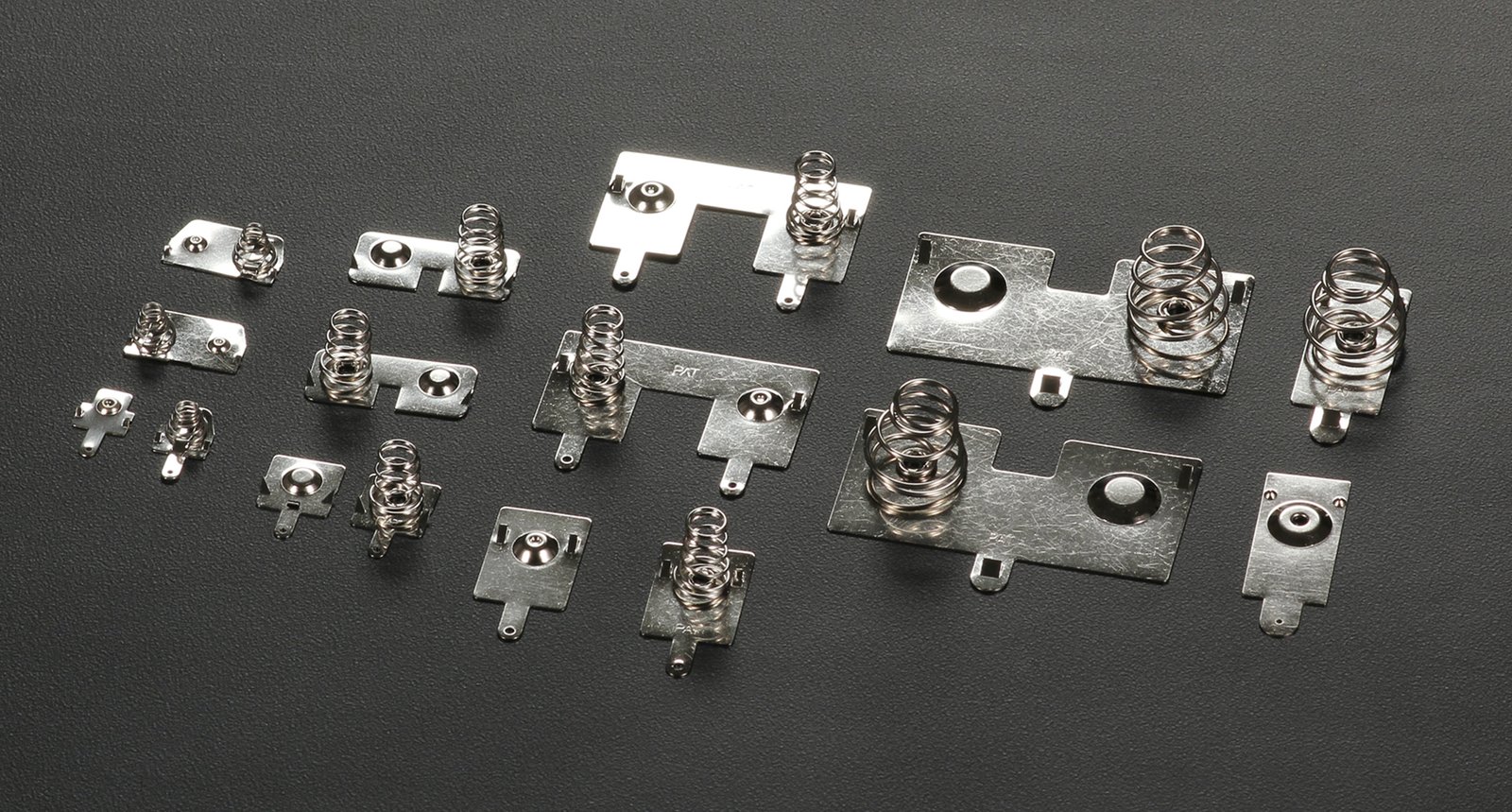

2. Battery Spring

– Common Materials:

– Nickel-Titanium Alloy: Flexible, corrosion-resistant, and perfect for battery connections.

– Stainless Steel (304, 316): Strong, durable, and ready to take on long-term battery use.

– Phosphor Bronze: Low resistance, excellent conductivity—perfect for electrical contact.

– Tip:

– For conductivity, go with phosphor bronze or nickel-titanium.

– Need anti-corrosion magic Stainless steel works, but keep an eye on that conductivity.

– For heavy use, nickel-titanium’s fatigue resistance will keep your springs going strong.

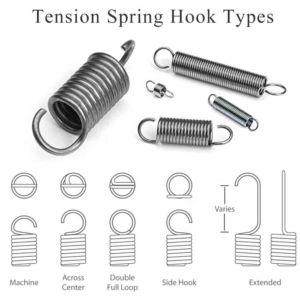

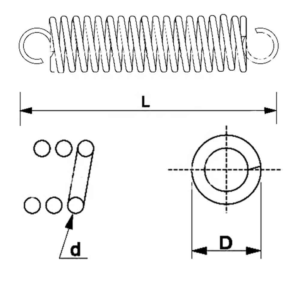

3. Tension Spring

-Common Materials:

-High Carbon Steel (60#): High strength, great elasticity—solid for tension applications.

-Stainless Steel (301, 304): Corrosion-resistant, perfect for humid or harsh environments.

– Alloy Steel (T9, T10): Built for heavy-duty work—high strength, high heat.

-Tip:

– Outdoors or humid? Go for stainless steel.

– Need strength and durability? High carbon steel or alloy steel will handle the load.

– Want your spring to last? Heat-treated materials will fight fatigue.

**Bonus Material Tips**

– Hardness & Elasticity: Heat treatment can give your spring a serious performance boost.

– Surface Treatment: If corrosion’s a concern, go for nickel plating, zinc plating, or oxidation to keep your spring shiny and rust-free.

– Fatigue Resistance: If your spring’s going to bend a lot, materials like stainless steel or alloy steel with high elastic modulus will give it a longer life.

– Manufacturing Process: The right process can make or break your spring. Precision cold processing helps with complex shapes and gives you better surface quality.

Choosing the right material doesn’t have to be hard—just match it to the job and keep these tips in mind!

Reviews

There are no reviews yet.